Rotary screw compressors in a class by themselves. Ingersoll US R-Series compressors offer the best of time-proven designs and technologies with advanced features to ensure the highest levels of reliability, efficiency and productivity. Total Air System (TAS) option provides clean, dry air in an integrated package Features a high-resolution color display and intuitive operation for easy compressor control. An integrated, intelligent system that continuously monitors key operating parameters and adapts to prevent unexpected downtime. A totally integrated, leak-free design using stainless steel pipes and long-life metal-flex hoses. Improves efficiency, serviceability and noise level. OIngersoll Rand R-Series compressors include many advanced features that significantly lower lifecycle costs. Mix and match variable and fixed speed motors with singlestage or two-stage airends to achieve the exact level of performance and economy your operation and your budget require. Deliver up to 15% more air with a two-stage airend* than a single-stage compressor, while consuming the same amount of energy!US R-Series 37-160kW / 50-200hp

Request a quote

Total Air System (TAS)

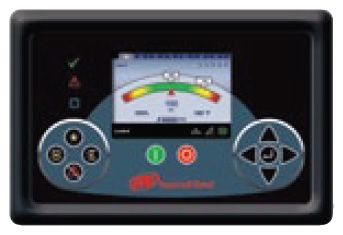

Xe-Series Controller

Precision Airends – market leading reliability and efficiency

Progressive Adaptive Control (PAC) Protection

V-Shield

Sequential Cooling

Innovative design, flexible choices