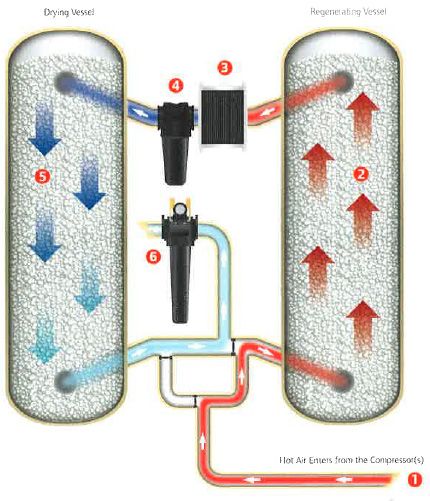

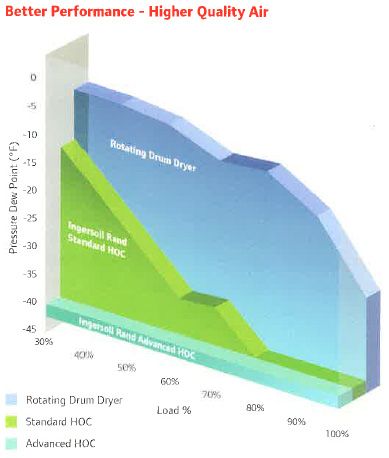

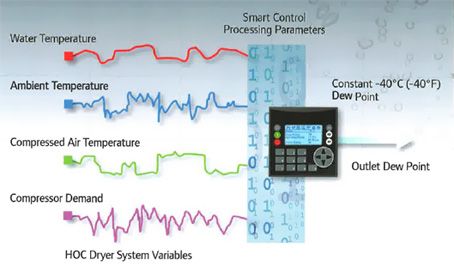

Clean, Dry Oil-Free Air: Ingersoll Rand heat of compression (HOC) dryers provide energy efficiency, flexibility, reliability and instrument quality air at operating costs well below those of typical desiccant dryer designs. 1. Hot air from one or more compressors enters the dryer. 2. Heat energy from the hot air removes moisture from the desiccant being regenerated. 3. Hot air enters the heat exchanger and is cooled causing moisture to condense. 4. Condensate is removed from the air through a moisture separator. 5. Air flows through the drying vessel, where any remaining moisture is adsorbed by the desiccant 6. Air exits through a filter providing high quality, instrument grade compressed air. Ingersoll Rand recognizes that each customer’s application is unique. That is why we designed our HOC dryers with flexibility to accommodate: The HOC dryer was also specifically designed with a low profile to facilitate ease of installation and maintenance as well as promote safety. Tried-and-true components, combined with innovative tedrrology, yield reliable HOC dryers. Performance. Os secadores Ingersoll Rand HOC fornecem consistentemente um ar limpo e seco para processos críticos. The new full-featured controller on Ingersoll Rand HOC dryers is user-friendly to set up and intuitive to operate Reliable, high quality air-lngersoll Rand Advanced HOC dryers use Smaft Control to adapt dryer operation to system and, o environmental changes, ensuring a constant -40’C (-40″F). Smart Control continually scans environmental and system parameters and make adjustments to minimize temperature fluctuations and provide air at a constant dew point. The problems created by having moisture in your compressed air system can range from an annoyance to wreaking havoc on your equÍpment and end products.Heat of Compression Dryers

Request a quote

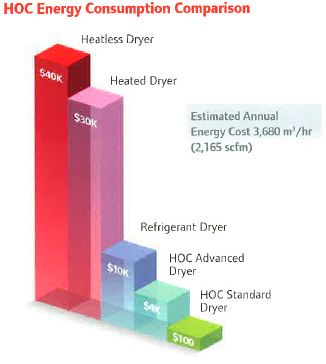

Energy efficiency

HOC at work saving you energy

Flexibility to accommodate your application

Reliability you can count on

Superior features, solid dependability

Full-featured controller comes standard

How smart control works

Why smart control