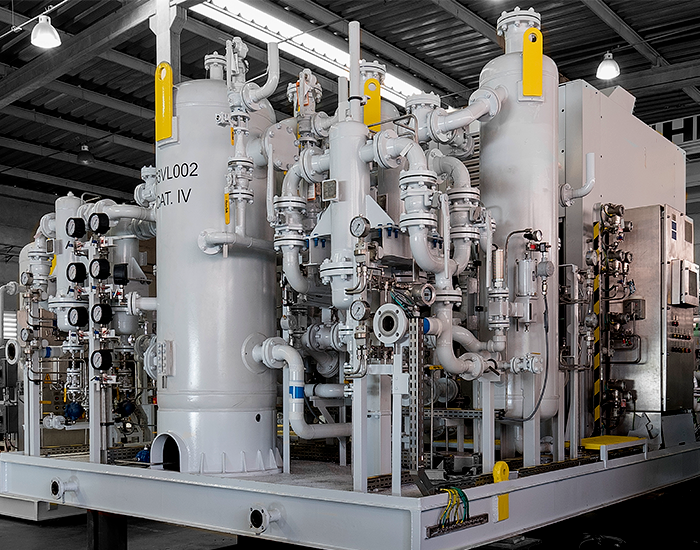

HBR API 619 P-SERIES are the ultimate solution for a compact, skid mounted, high performance air compressor system. THE HBR P-SERIES are provided on dry-screw or oil flooded technologies, fully assembled and tested for onshore and offshore application including FPSO-ready models with integrated dryers, heat exchangers and micro processed control panel, ready to be lifted on board. Instrument air compressors that comply with API 619 standards are designed to be robust, reliable, and efficient, capable of handling demanding operating conditions. Additionally, they are engineered to be an oil-free compressor, ensuring purity in air compression processes. Engineered Equipment

Typical main specification:

Model

Stages

rpm

Flow @ 10 bar(g)

Nm3/hHP Motor

IAC 300

2

1775

1606

300

IAC 350

2

1775

1957

350

IAC 400

2

1775

2325

400

IAC 450

2

1775

2628

450

IAC 500

2

1775

2942

500

IAC 600

2

1775

3308

600

IAC 700

2

1775

4049

700

IAC 800

2

1775

4756

800

Pricing and Availability