Ingersoll Rand’s Nirvana Cycling Refrigerated Dryer provides reliability like no other dryer in its class: reliability that you can count on to protect your air system day in and day out; reliability built in by design.

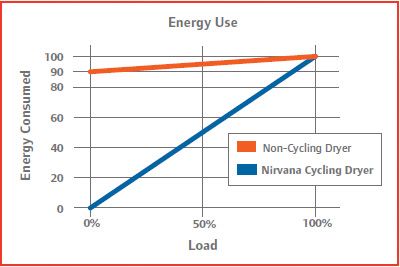

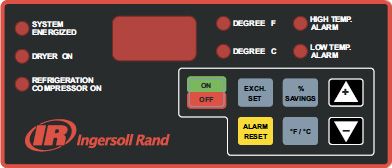

The Nirvana is a genuine cycling dryer, incorporating innovative features that make it not only the most reliable, but the most energy efficient, dryer in its class. The key element central to the Nirvana’s reliability and energy efficiency is its distinct, patented heat exchanger design. Providing high heat transfer with low pressure drop because of uniquely short flow length, the Nirvana heat exchanger presents a flow area three to five times that of an equivalent copper tubing exchanger, and it is self-cleaning, which greatly reduces the potential for fouling. 1 – An innovative corrugated and folded stainless steel panel is stacked inside two stainless steel shells, then welded together to form a unitized heat exchanger. This design ensures reliability through the elimination of dissimilar metals or tube in tube chaffing, which is a common cause for heat exchanger leaks and failures. 2 – 100% stainless steel construction permits optimal heat transfer, resulting in a consistent pressure dew point. 3 – Nirvana dryer’s heat exchangers combine a high heat transfer coefficient with unmatched low pressure drop. 4 – Corrosion-resistant 304L stainless steel is used in all the Nirvana dryer’s heat exchangers, providing durability in environments unsuitable for copper or other metals. An advanced cycling dryer, the Nirvana provides significant savings because it does not waste energy costs through continuous operation of its refrigeration system, as do traditional non-cycling dryers Nirvana cycling dryers up to 2,400 SCFM are equipped with ENL condensate drains, which eliminate venting of compressed air to the atmosphere and are more reliable than traditional float- or solenoid-type drains. The Nirvana cycling dryer uses centrifugal separation to remove moisture from the chilled air. Separation occurs at the coldest point in the system by means of centrifugal acceleration, then expands into an area of low velocity containing a sump, and change of air flow direction. The result is highly-efficient moisture removal, providing exceptionally dry, clean air under all operating conditions. The easy-to-use controller automatically manages dryer operation for optimum air treatment and for maximum energy efficiency.Nirvana Cycling Refrigerated Dryers

Request a quote

The most reliable, the most energy efficient

High heat transfer at work

Energy-efficient design

Electronic no air loss (ENL) drain

Best in class design

Microprocessor controller