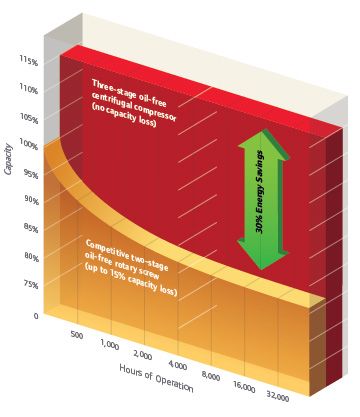

Ingersoll Rand introduced the first oil-free centrifugal compressor in 1912, and over the decades we’ve continued to develop rugged, reliable, industry-leading compressor technologies. Ingersoll Rand has become the leader in oil-free centrifugal compressed air because our technological advances are designed for the specific performance needs of our customers’ industries. No matter what the application, Ingersoll Rand centrifugal compressors help eliminate inefficiencies, contaminants and breakdowns that can result in costly downtime, product liability or damage to your brand reputation, while reducing total lifecycle costs. The first to be certified ISO 8573-1:2001 Class 0, our oil-free centrifugal compressors offer efficient, economical and reliable solutions for delivering compressed air. These highperforming, versatile compressors provide 100% oil-free air in all operating conditions. Ingersoll Rand centrifugal compressors offer up to a 15% capacity advantage over competitive two-stage, oil-free compressors. This advantage increases to as much as 30% as our capacity remains constant, while competitive capacities decrease by up to 15%. Optimize Your Compressed Air System with Xe-Series Controls. The Ingersoll Rand Xe-Series controller uses the latest control algorithms to help lower energy consumption. Built-in control logic ensures system reliability by precisely managing discharge pressure and maximizing throttle range. The controller’s intuitive, high-resolution color display makes critical information quick and easy to find. And with web-enabled alerts, the Xe-Series controller helps you maintain optimal operation automatically.Centac® Centrifugal Air Compressors

Request a quote

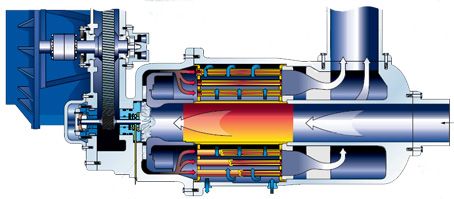

Superior Design, Superior Life

Optimized Components and Systems / User-Friendly Operation and Accessibility

Oil-Free, Risk Free

Greater Capacity for Greater Efficiency

Advanced Centrifugal Control

Low Pressure 0.35-2.10 bar g (5-30 psig)

Model

CH5

CH6

Standard Pressure 3.1-10.3 bar g (45-150 psig)

Model

C400

C700

C1000

3CII

C3000

5CII

High Pressure 10.3-42.0 bar g (150-610 psig)

Model

2CII

C750

C1050

3C

4C