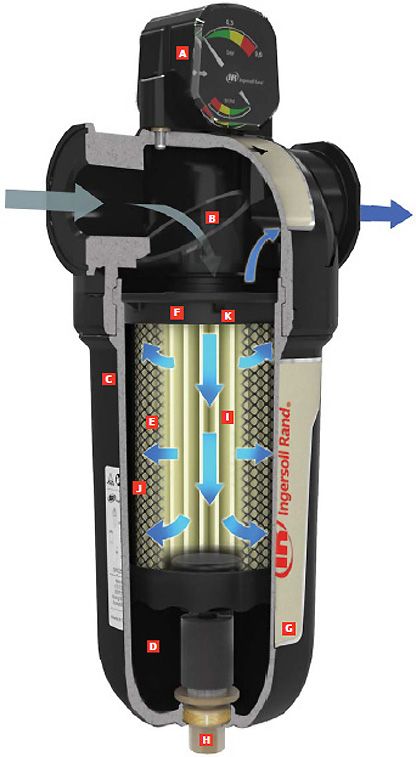

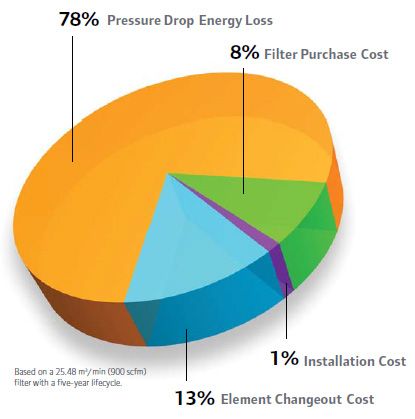

Ingersoll Rand’s advanced F-Series compressed air filters reduce contamination in your air stream to help protect your critical processes and valuable equipment. Our filters are rigorously tested and engineered with superior components to provide years of reliable performance and consistently high-quality air. Without effective filtration, products and processes that depend on compressed air are subject to increased scrap, poor quality and additional maintenance. Ingersoll Rand F-Series filters address these issues, helping to assure your compressed air system delivers clean, high-quality air throughout your facility. Maintaining a low pressure drop on all compressed air components is critical for an energy-efficient system. Ingersoll Rand F-Series filters have been engineered to deliver low pressure drop throughout the life of the fi lter element and to provide a unique dual indicator that illustrates the true cost of pressure drop on the system. Every compressed air system has unique fi ltration requirements. F-Series filters are available in four different filtration grades, providing complete filtration solutions for all critical compressed air processes. A Patented dual indicator shows differential pressure drop and economical operating efficiency B Patented smooth bore flow insert directs air into the filter element, minimizing turbulence and pressure losses C All-aluminum, precision die cast body suitable for 80°C (176 °F) and 17 bar g (250 psig) MAWP applications D Proprietary coating applied to the inside and outside surfaces provides corrosion protection in harsh industrial environments E Filter element with stainless steel mesh withstands high differential pressure while minimizing flow restriction through the element F Ergonomic bowl design with no-touch filter element simplifies element replacement G Time strip label indicates when it’s time to change the element (A Grade only) H Industrial-grade brass float drain discharges accumulated condensate and oil more reliably than lesser quality plastic drains (no-loss and manual drains also available) I Deep-pleated filter media reduces air flow velocity to maximize filtration efficiency and minimize pressure losses J High-efficiency drainage layer improves liquid drainage properties and enhances chemical compatibility K Simple visual alignment of the filter head and bowl ensures accurate assembly of components and helps to improve safety F-Series filters are engineered to be a complete filtration solution, incorporating features that address air quality, energy efficiency and ease of maintenance. Quality Assured The standard for high-quality air F-Series filters provide clean, high-quality air as defined by ISO 8573-1:2010, and are certified by a third party under ISO 12500-1:2007. With multiple filter element grades available, there is a filtration solution that will meet your unique requirements. Energy efficient through and through Pressure drop accounts for over three-quarters of the ownership cost of a compressed air filter. Even when a filter element is clean and dry, it can rob a compressed air system of pressure, causing the air compressor to work harder and increase energy costs. The flow path through the F-Series filter housing reduces turbulence and enhances efficiency, while the deep-pleated element design further minimizes pressure drop. Designed with maintenance in mind * *Frequency of element changeout will depend on the unique conditions of each customer’s air system.F-Series Filters

Request a quote

Better quality

Better efficiency

Better choices

Superior filtration technology

Complete filtration solution