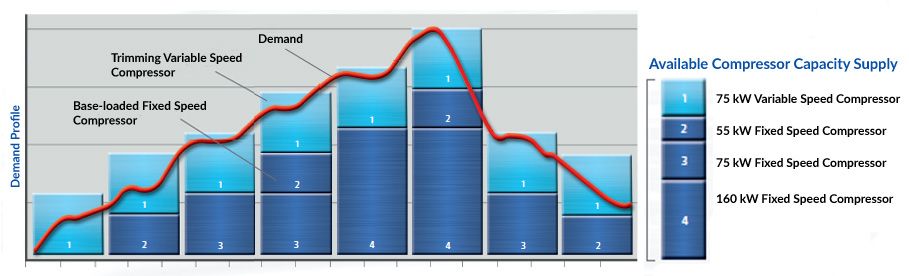

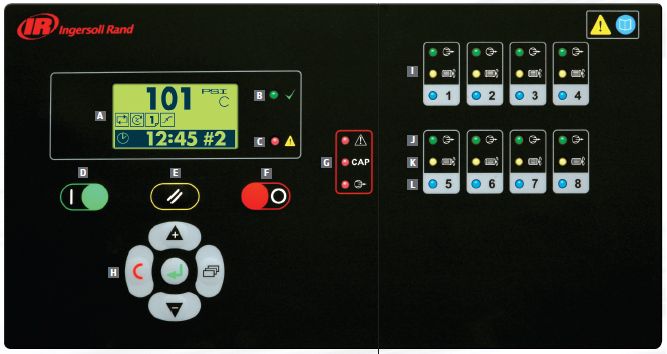

As much as 20% to 60% of the energy used to operate compressed air systems is wasted. This is primarily due to operating more compressors than necessary, operating the wrong combination of compressors or maintaining elevated system pressure. Ingersoll Rand X8I System Automation can help reduce operating costs, while maintaining confidence in a sufficient and efficient air supply at all times. Ingersoll Rand X8I System Automation can manage up to eight positive displacement compressors – including compressors of different capacities, different types (fixed speed, variable speed and variable capacity), and in any combination or configuration. Through advanced control functionality and universal connectivity the X8I will work with your existing compressors, from Ingersoll Rand or any manufacturer, to improve operating efficiency and reduce energy costs. The X8I continuously monitors and “learns” the demand requirements of the system by comparing pressure dynamics with compressor operating capabilities and control reaction. Adaptive control logic and advanced control algorithms are used to implement a “best fit” compressor combination and configuration strategy. The X8I is designed to effectively and efficiently manage your air compressors’ capabilities to meet and match the dynamic demand variations common to almost all systems. The primary function of Energy Control Mode in Ingersoll Rand X8I System Automation is to: Communication and Control at The Heart of Your Air System. Connectivity, Ingersoll Rand X8I System Automation is one air system control solution that quickly pays for itself, without compromising any of your previous compressor or air system capital investments. It is uniquely configurable and customizable to meet the specific needs of some of the most complex compressed air systems. Additionally, the X8I network can be expanded to include monitoring and control of additional compressed air system components. And beyond paying dividends in energy savings, it also provides ancillary savings in terms of labor, maintenance and resource utilization – here’s how: Versatile Networking. Manages up to eight positive displacement air compressors from any manufacturer, located up to 4,000 feet away from the controller! Energy Control Mode. Adaptive control logic dynamically selects and utilizes the most efficient set of compressors to meet air system demands. Anti-cycling. Continuous monitoring of system pressure and rate-of-change; uses advanced control algorithms to prevent unnecessary compressor cycling. Single-point Control. Manage multiple compressors to one optimal control band or target. Priority Compressor Selection. Minimize energy use by programming units or groups for optimum utilization and/or operations planning – including equalized usage. Custom Pressure Selection. Four programmable pressure profiles – optimize system operation for specific production requirements. Controlled Operations. Fully-adjustable time parameters help implement smooth, controlled schedule changes from one “target” pressure level to another. Real-time System Scheduling. Configure control features including system standby and system prefill based on a real-time schedule. Network Expandability. Integrate new compressors and distributed control through networked, intelligent I/O. Easy Set-up/Operation. Improve your ability to optimize air system savings with an intuitive graphical interface for configuration and system information. A better way to view your system Simply add a VX module to any X8I or X12I network, complete some basic configuration, connect to your Local Area Network (LAN) or directly to a PC and view your compressed air system on your computer monitor. No special software is required. With X-Series System Visualization you can monitor critical system and equipment parameters, drill down to individual compressors to view operational status and be alerted to any alarm messages. Complete system viewing from a local or remote PC has never been easier.Advanced Air System Control

Request a quote

Now you can cut operating costs with your existing equipment!

Tailoring supply to demand

Minimize wasted energy and costs

X-Series System Visualization

X-Series System benefits

Max. # Units

8 Compressors

Dimensions (LxWxD)

13.4” x 9.45” x 6.0”340 mm x 241 mm x 152 mm

Weight

16.5 lbs (7.5 kg)

Mounting

Wall, 4 x screw fixings

Enclosure

IP65, NEMA 4

Power Supply

230 VAC +/- 10% (50 Hz)115 VAC +/- 10% (60 Hz)

Temperature

32°F to 115°F (0°C to 46°C)

Humidity

0% to 95% Rh Non-condensing