Proven performance and backed by an industry leading 5-year warranty, ARO air operated diaphragm pumps are a truly versatile fluid handling solution for numerous applications. Known for industry-leading efficiency, reliability, and flow rates, and a large range of materials and porting, ARO has the right pump to deliver consistency in the most demanding situations. ARO range of air operated diaphragm pumps offers many materials of construction. Our metallic offering consists of aluminum, cast iron, stainless steel and hastelloy®. Our non-metallic offering consists of polypropylene, acetal and PDVF. All ARO pumps are available with convoluted diaphragms offering long product life and reduced maintenance. Air operated diaphragm pumps are designed for general use. They can easily pump from clean, light viscosity fluids to corrosive, abrasive medium viscosity fluids and can transfer large particles without damage. Due to their pneumatic motor, they could be used in potentially explosive areas. Most of the ARO® diaphragm pumps are ATEX certified (CE Ex11 2GD X). These pumps offer the ability to vary the flow outlet and discharge pressure as slow as 0.26 gallons (1liter) per minute up to 275 gallons (1041 liter) per minute for our larger sizes and adjust fluid pressure up to 125 p.si. (8.6 bar), by using just an air filter / regulator and a needle valve Metallic: Non-metallic: Ceramic Mining General Chemical Industry OiL & Gas (onshore / offshore) Dangerous ChemicalsARO Series Diaphragm Pumps

Expert Series

FDA Compliant

PRO Series

Everything you need, nothing you don’t

Features

Find your EXP opportunity

Why ARO diaphragn pumps?

Building materials

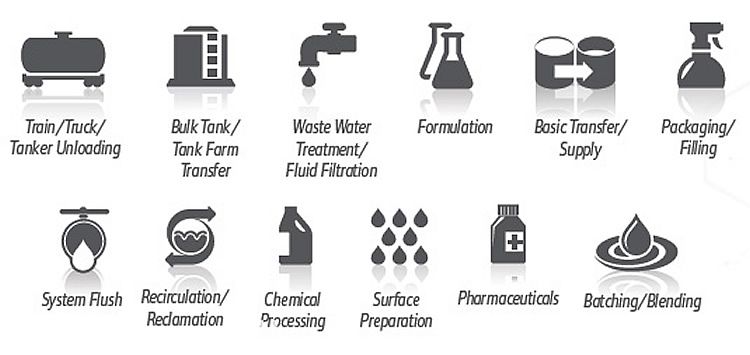

Industrial Applications: