26/09/2017 -

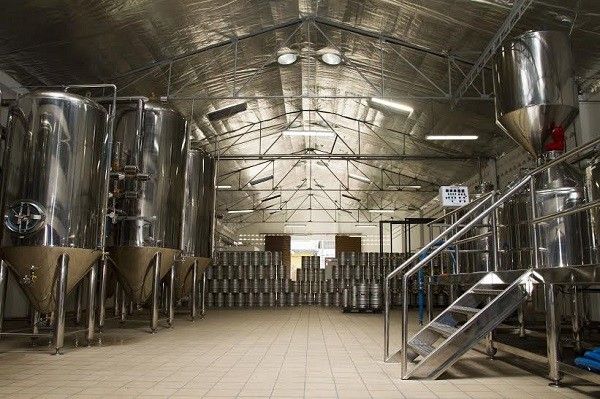

The article deals with the benefits of using the local nitrogen generator in the beer industry Nitrogen and other compressed gases are used at various stages of the fermentation process. Breweries use nitrogen for: Inerting tanks between uses, it can be used to shift oxygen and carbon dioxide into tanks and push beer from one tank to another. Nitrogen is also injected to pressurize the barrels for shipping, storage and use. Producing nitrogen at the site offers brewers and microbrewers three key benefits, with far greater advantages than buying nitrogen: 1. Minimal waste of time: Excludes possible interruptions in production, since it is not necessary to be at the mercy of a nitrogen supplier. When the gas is brought, it needs to be connected to the system and the old containers need to be removed, with the nitrogen being produced on the spot this is no longer a concern. 2. No waste: While the purchased nitrogen is inactive in the tanks, ambient heat causes it to expand, if the pressure is not released, the tank may explode. So the tanks have to be opened and the gas goes into the atmosphere. This is a waste of money and the gas itself. With the generator, only the necessary is produced, reducing costs. 3. Lower costs: On-site nitrogen generation is clearly cheaper than buying carbon dioxide or nitrogen. Depending on purchase and delivery costs in an area, brewers can achieve savings of 40 percent to 75 percent by choosing to use on-site nitrogen generation. The various benefits of local nitrogen generation boil down to one common theme: economics. Lower gas expenses, less gas waste and no waiting time for delivery and installation, nitrogen generators are a clear advantage for brewers. Brewers can save more by combining nitrogen generation with oil-free air compressors, cutting production costs and bolstering their bottom line.