11/01/2018 -

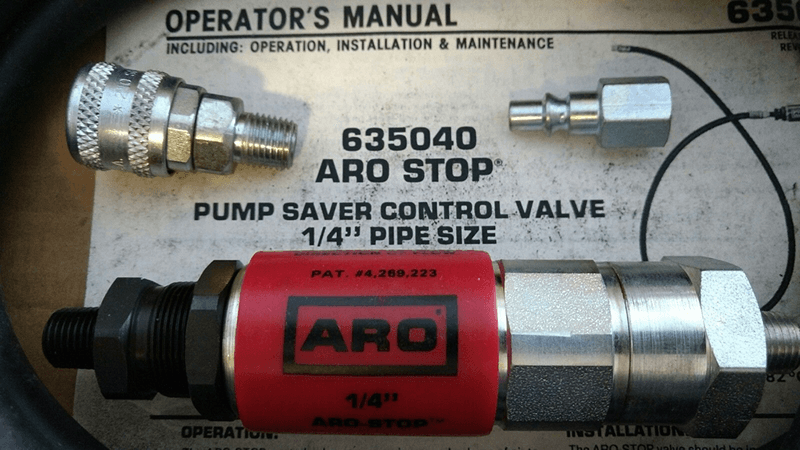

Reduce the consumption of compressed air by preventing the pneumatic pump from operating dry Typically, a double diaphragm pneumatic pump operates in “automatic mode”, ie without proper supervision. It is common to find this type of pump operating dry, without pumping any type of fluid and generating high expenses for the system, in different ways. In addition to the natural wear and tear of all pump components, such as seats, diaphragms, balls, sealing rings and other moving parts of the pump system, there is also a very high expenditure of compressed air, a source of energy with high operating costs. This greatly increases system costs. To prevent such problems, we suggest using the Air Stop Valve (ARO), which prevents pneumatic pumps from operating dry after the end of the pumping cycle, considerably reducing compressed air consumption and increasing the life of the pump. equipment.